The modern artisan loves to work with their hands, but also loves to use power tools to help make their craft. At JUstenbois, we use our hands, our hearts, and our heads to make the highest quality wooden utensils as beautiful and as consistent as possible.

As a business we have developed special equipment that allows us to lessen manual work and at the same time increase productivity to make our wooden utensils accessible to more people.

When an artisan approaches a project, they are always looking for ways to make their design attractive and unique. When making a set of wooden utensils, there is a balance that needs to be achieved to have uniformity in design while ensuring that each piece is functional.

When the artisan is trying to make these designs a business, part of the art is also making it possible to easily reproduce.

It all started with the size and shape. After a full review, we determined that an 8” length was the perfect size for an adult wooden utensil. Then trial and error on design took place. The love of modern simplistic design led us to the beautiful, curved lines of our wooden utensils.

Once the design was determined, the art of figuring out how to reproduce the design as consistently and quickly as possible was evaluated. This required the making of special jigs, the acquiring of special equipment, and the development of unique processes to increase productivity.

This can sometimes be more creative than making the wooden utensil itself. Go to our 7 steps to make a wooden utensil below to see our creativity.

The selection of the right kind of wood for your utensils is essential to making quality pieces that will last a long time. At JUstenbois we use sugar maple that is kiln-dried. Our explanation of the types of wood will help you to understand why.

There are two kinds of wood: softwood and hardwood.

Softwood typically comes from conifer trees that usually remain evergreen. This includes spruce and pine wood. These trees tend to grow faster and as a result, are less dense. The lower density makes softwood easier to work with. For example, it is used in construction as it will take screws and nails easier with a lower risk of splitting. You don’t have to predrill to screw.

Hardwood typically comes from deciduous trees that usually lose their leaves annually. This wood includes oak, mahogany, walnut, and maple. These trees tend to grow slower and as a result, they are denser. This density of wood is important for making utensils because it makes them more durable and resistant among other traits that we will get into later. Good quality hardwood is not as readily available as softwood, which makes it more expensive.

At JUstenbois we have reviewed the qualities of all hardwoods and found that Sugar Maple is one of the best woods for cooking, serving, and eating for these reasons.

Sugar Maple is resistant to dents, scratches, splitting, and wear and tear. It has a Janka rating of 1,450 lbf, which makes them not only perfect to use, but a little easier to work with. A JUstenbois wooden utensil can last up to 15 years with proper care.

In choosing a hardwood to make utensils it is important to know if it is toxic. A number of wood species are known to be toxic. They can cause an allergic, infectious, or respiratory reaction. Sugar Maple is not toxic.

Sugar Maple is neutral, it is odourless and flavourless. Wood with high tannins can transfer its flavour into food and change its taste. Since Sugar Maple is neutral, the use of wooden utensils made from maple will not transform the taste of your food, nor will it change the nutrients of the food.

Sugar Maple is a hardwood with a very close or tight grain. The tight grain does two things, it reduces infiltration, which prevents bacteria growth and any bacteria that is absorbed, gets trapped and is prevented from resurfacing. Eventually, the bacteria die naturally while the utensil dries.

This occurrence is just like what a tree does to fight bacteria. Even though the wood is no longer a living tree, its cells are still the same and don’t permit bacteria from growing. Maple Wood is naturally more antibacterial than any man-made material.

Another advantage of Maple that prevents bacteria growth is that it is less likely to crack in water. It is the cracks in the wood that can cause bacteria to form. So, wood that does not crack will prevent bacteria from forming.

Sugar Maple Wood is a natural, renewable resource. Very little wood is used to make wooden utensils. At JUstenbois, around 9,000 utensils are crafted from one maple tree. We also choose Maple Wood which comes from cultivated trees that follow sustainable management practices.

We only use mature trees; their removal allows for younger trees to grow faster. This captures more carbon dioxide. Also, wood is 100% biodegradable.

Sugar Maples love the cold like Canadians must, to endure the winter. Not only do the cooler temperatures in the fall produce those eye-catching colours, but the change from cold to milder temperatures in the spring also produces the maple syrup that we love. This colder climate also makes the trees hardier. This hardier nature makes the wood more resistant to cracking and splitting.

At JUstenbois, we have chosen to only use Kiln dried wood. Kiln drying is the process of drying wood in a kiln. The process sucks the moisture from the wood and kills any insects in the wood. Kiln dried wood is more stable, less susceptible to shrinkage, more resistant to bugs and fungus, and stronger.

Part of the stability of kiln-dried wood is its uniformity. This means that the wood is dried through and through, the middle as dry as the outside. Another aspect of the stability is that the moisture content can be at a specific consistent level. This stability in the wood makes our wooden utensils of the highest quality on the market.

There are many steps to making a wooden utensil. Each wooden utensil has specific steps that are unique to that utensil, but there are many steps that are similar. We will do our best to explain each step and which utensils require that step.

Each wooden utensil requires a different width of wood, with spoons requiring wider wood than forks or knives. We start by running the wood through the planer to smooth the surface and bring it to the exact width required to make the utensil.

We then cut the wood into blocks (slightly more than eight inches) in the case of both forks and spoons for adults. For knives we leave them in thirty-six-inch blocks and cut strips.

Here the process for both forks and spoons are the same. The process for knives is different. We have created a jig to help with the shaping of the curves for the wooden utensil. We have also created a jig to help with the forming of a blade for knives.

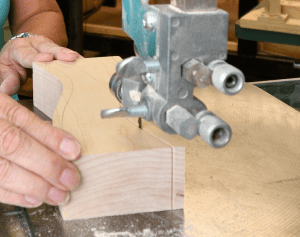

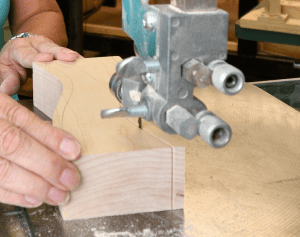

We start by using a template and drawing a curve on the block of wood. We then use a band saw to cut a slice of wood.

To improve one side of the slice and provide a smooth consistent surface to form the next slice, we use a jig and run the remaining block of wood along a wood shaper.

In the case of knives, we use a jig and the wood shaper to form the blade. We run the thirty-six-inch strips through the shaper twice to make a “V.” We then cut the strips into eight-inch slices.

There is an extra step for spoons. We will start there. Spoons require a bowl to hold liquids. We have developed a special boring tool on a router to make the bowl. We use this tool to bore a bowl in the formed slice for spoons.

We then follow the same process for spoons and forks, which is cut the utensil out of the formed slices that we have made. We have developed special jigs to hold the formed slices for each product in place while a CNC routing machine cuts and forms the fork or spoon.

In the case of knives, we use two special jigs (one for each side of the knife) and the shaper to form the shape of each knife.

When making spoons and forks there is excess wood left on the rough formed cuts. We use the band saw to remove the excess wood.

We use a chain of four machine sanders that each make little adjustments to the wooden utensil, make the final shape of the outer utensil, remove rough edges, and smooth out the wood. In the case of knives, we use machine sanders to make the blade sharper and smooth the surface and edges.

As time-consuming as it is, there is no replacement for the human touch. We have a 2-part hand sanding process to make the surface of the utensil as smooth and satin-like as possible. Hands can get where the machines can’t, like in the bowls of spoons, in between each tine and forming the points on a fork, or putting the final touches on the blade of a knife.

We sand the entire surface of the wooden utensil continually touching the surface to make sure that it is smooth. Once we are satisfied, we finish by sanding the entire utensil again with 600-grit sandpaper.

At JUstenbois we apply three very thin coats of a unique combination of food-safe natural resins. We let each coat dry for 24 hours between coats and will not let them be used for 21 days after the application of the last coat.

We take pride in our creations and will always work to ensure that our customers receive the highest quality wooden utensils and dishes with the best level of service. All our products are inspected using a magnifying glass to try to find even the smallest imperfection. We also use our fingers and touch every surface to ensure that it is smooth and that there are no hidden defects not visible to the eye even with a magnifying glass.

Occasionally there are hidden defects in the wood, that only emerge with use. That is why we stand by our products and provide a one-year warranty on wood cracking, splitting, and manufacturing defects.

Subscribe to our newsletter

Stay up to date with new products and news. Subscribe to our newsletter below:

JUstenbois’ eco-friendly wooden utensils and dishes are part of the current cultural awakening for an environmentally friendly, healthier way to eat.

We have been developing our expert techniques since 2004.